LDAR program implementation: reducing fugitive emissions of volatile organic compounds (VOCs)

LDAR (Leak Detection and Repair) programmes are intended to reduce fugitive emissions of volatile organic compounds (VOCs), with the resulting occupational risk reduction and wastage reduction of raw materials and products.

This service is targeted at companies that use raw materials or products containing volatile organic compounds and aims to:

- Determine the diffusion of fugitive emissions of organic compounds.

- Reduce the risk of explosion by emissions of organic compounds.

- Reduce wastage of raw materials or products.

The LDAR programme’s implementation procedures follow the refining, petrochemical and advanced chemical sector’s BAT (Best Available Techniques) programme.

A LDAR programme comprises the following stages:

- Stage 1: Component identification

At this early stage, and in order to improve programme outcomes, a meeting is held with the plant to request the minimum documentation required to identify the components of each work area and consequently the elements likely to be inventoried. In addition, a LDAR technician will conduct a preliminary inspection and an IR scan at the plant.

- Stage 2: Leak definition

In order to regulate and set the LEAK levels, VOC measurements have to taken in parts per million (ppm), so that a leak can be distinguished from a concentration level that moderately exceeds the legally established or recommended level.

After defining the LEAK levels, it is necessary to establish safety margins linked to three priority levels for intervention, according to the requirements of the plant.

- Stage 3: Component monitoring

Monitoring is carried out in 2 combined stages: detection and quantification-calculation, involving both Applus+ and their partner company, The Sniffers.

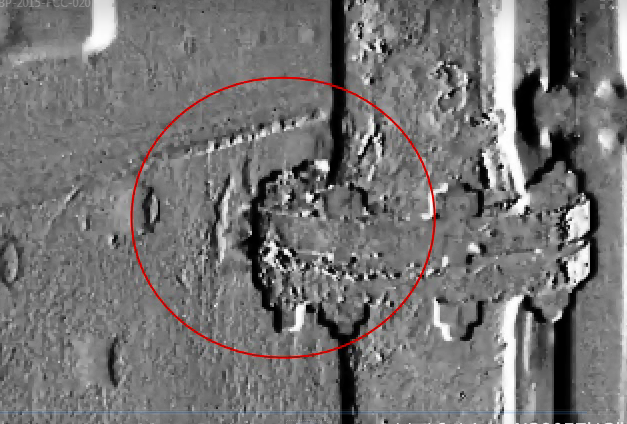

Detection: the FLIR GasFindIR infrared detector can quickly and easily identify leaks of volatile organic compounds. It is able to scan large areas of pipes and allows for the real-time imaging of gas leaks. During the IR monitoring, detailed information is collected on each leak source, enabling an analysis of or further investigation into the data collected.

Quantification-Calculation: All the leaks identified by the camera are monitored to quantify the level of the leak by way of a photoionization detector (PID). PIDs measure halogenated hydrocarbons, aldehydes, ketones and all compounds that can be ionised by ultraviolet light.

- Stage 4: Component repair

The plant is responsible for carrying out the maintenance and/or repairs required to eliminate or reduce the leakage. Applus+ commits to re-monitoring each of the leaks repaired after the plant has reported the end of all intervention works.

- Stage 5: Record maintenance

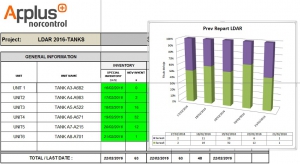

Component cards will be created to document all the components and their measurement points, indicating the presence or absence of leakage in each of them and the quantified values in case of leakage.

Plant staff have access to all of this information by way of the Applus+ Apportal work platform. Applus+ can also provide a specific software or data-processing programme if requested.

Organization and tools

The Applus+ technical team responsible for methodological development consists of an Applus+ project manager, a LEAD expert technician from The Sniffers, an Applus+ inspector and a field technician.

The Applus+ technical team responsible for methodological development consists of an Applus+ project manager, a LEAD expert technician from The Sniffers, an Applus+ inspector and a field technician.

Equipment necessary for the execution of the works includes an IR camera for leak detection and a FID (PID) detector-meter, as well as auxiliary and computer equipment.