Eddy Current Testing has various applications:

In weld inspections, it can be used to detect cracks in the weld cap, weld toe, or heat-affected zone. Because the eddy currents are not affected by the presence of a non-metallic coating, a paint layer or other coating doesn’t have to be removed prior to the inspection.

Eddy Current Testing can also be used for detecting cracking in other metal objects, such as pipes, tanks, and structures like bridges.

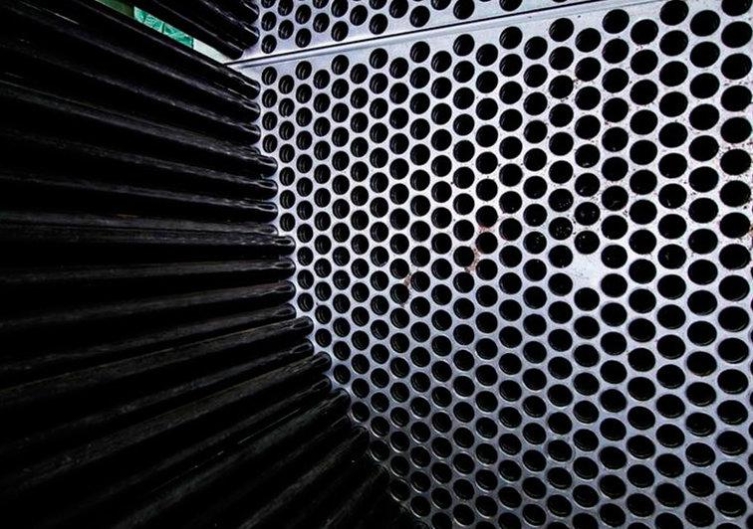

A widely used application of Eddy Current Testing is the inspection of heat exchanger tubes. With an internal bobbin coil probe, heat exchanger tubes can be examined at a relatively high speed. Although the tubes are examined with an internal probe, defects on both the inside and outside of the tube can be detected. Defects, such as internal and external pits, wall loss, or baffle wear, can be detected and sized. Defect indications are assessed immediately on-site and entered into the reporting software. As a result, we can typically provide a report with test results immediately after the inspection is completed. Although conventional Eddy Current Testing on heat exchanger tubes can only be applied to tubes of material that is non-magnetizable (for instance brass, titanium, most stainless steels), Applus+ can also provide eddy current based alternatives for tubes made of magnetizable materials like carbon steel and duplex steel: Remote Field Testing (RFT) and Eddy Current with magnetic saturation.

Another option for examination of heat exchanger tubes (both non-magnetizable and magnetizable tube materials) is our ultrasonic IRIS inspection.

Other Eddy Current-based NDT methods Applus+ provides include:

- Remote Field Testing: inspection of ferromagnetic heat exchanger tubes

- (Partial) Saturation Eddy Current: inspection of ferromagnetic heat exchanger tubes, including finfan tubes

- Incotest: detection of corrosion under insulation

- ACFM: detection and sizing of surface-breaking fatigue cracking

- SLOFEC: tank floor and pipeline scanning

ACFM - Alternating Current Field Measurement

Alternating current field measurement (ACFM) is an electromagnetic NDT technique capable of both detecting and sizing (length and depth) surface-breaking cracks in metals. The ACFM NDT technique alternates constant-current in a tangential solenoid, remote from the test surface, and induces electric currents in the sample surface, which are uni-directional and of uniform strength over a localised area under the solenoid. When no defects are present in this area, these electric currents will be undisturbed. If a crack is present, the uniform current is disturbed and the current flows around the ends and down the face of the crack. A standard PC is used to control the equipment and display results. ACFM is unique in the way data is displayed in this electromagnetic NDT process.

INCOTEST: Corrosion Under Insulation Inspection Tool

RTD INCOTEST (INsulated COmponent TESTing) is based on the pulsed eddy current principle to carry out PEC inspection in a wide range of industry sectors. Pulsed eddy current testing is a reliable way to survey ferrous pipes and vessels through their thermal insulation and protective coatings. Our jointly-developed PEC inspection technology is an excellent tool for prioritising corrosion under insulation inspections. In this technique, the sending coil generates eddy currents at the surface of the material. As they diffuse, they generate a magnetic field that is detected by the receiving coil in the NDT probe. The average remaining wall thickness within the enclosed magnetic field is proportional to the decay time of the received signal.

INCOTEST: Corrosion Under Insulation Inspection Tool

Get a quote Watch the videoInspection of ferromagnetic tubes by Remote Field Testing and Partial Saturation Eddy Current testing

Eddy Current testing is a non-destructive testing (NDT) method commonly used to inspect heat exchanger tubes. However, conventional eddy current testing can’t be deployed on tubes of ferromagnetic materials, such as carbon steel, due to the permeability (magnetic behavior) of the tube material. For inspection of ferromagnetic heat exchanger tubes, Applus+ utilises Eddy Current-based techniques, Remote Field Testing, and Partial Saturation Eddy Current, as well as the ultrasonic IRIS technique.