Storage Tank Inspections & Calibration Using Laser Scanning

3d modeling and laser technologies have been employed throughout various industries to varying degrees over recent decades. The industrial sector has identified opportunities for laser technologies to aid in many tasks that were previously thought to be time-consuming and ineffective. Photogrammetry services have provided time- and cost-efficient approaches to data collection and increased data quality to a level unobtainable through manual measurements.

This article on Storage Tank Inspections and Calibration utilizing Laser Scanning method will form part of a series of articles discussing laser testing methods, such as as-built documentation, BIM modeling, and other advanced laser analysis.

Owner-operators are obligated to ensure the integrity of their assets surrounding continued service in accordance with multiple standards and codes. Efficiency is key to keeping overall costs down while providing key information needed to assess integrity.

Applus+ RTD is excited to offer a complementary method of inspection for storage tanks using laser scanning, and advanced tank analysis software. Utilizing laser scanning technologies for your tank inspection needs is, efficient, cost effective, and delivers 2cm accuracy – within a relatively short time span. Most tanks can be scanned in their entirety within 1 day, including both internal and external surfaces, and high quality deliverables can be generated from point cloud data acquired shortly thereafter.

Here’s how it works:

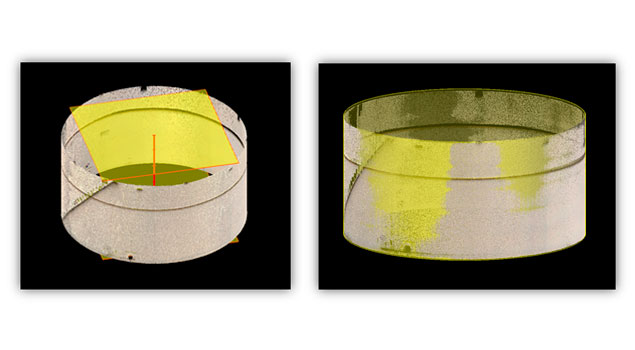

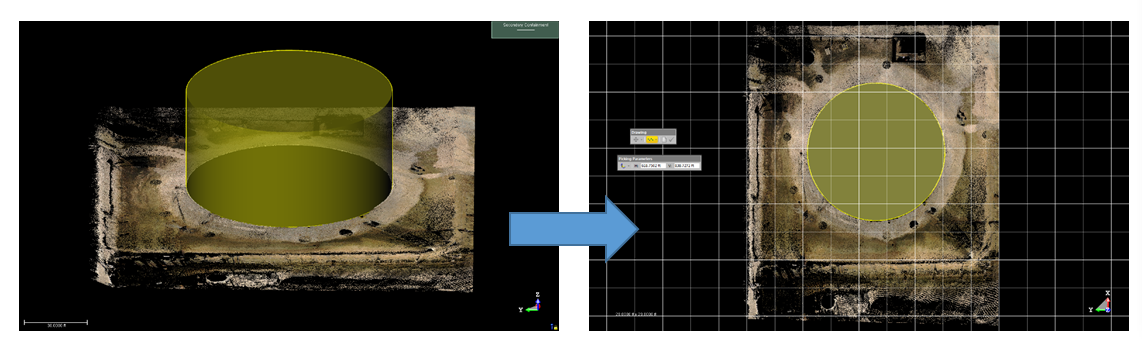

First, we begin with collecting data on the tank itself, which is accomplished by utilizing FARO laser scanning products. The tank is scanned completely around the outside/inside and generates a “point cloud” of data. This point cloud serves as the foundation for advanced analysis, modeling, and even CAD creation if so desired. Using advanced tank analysis software, we are able to measure and determine the following attributes of the tank:

- Beam / Column Inspection

- Calibration / Volume Calculation

- Containment Analysis / Spill Point Identification

- Floor Inspection / Edge Settlement

- GIS Analysis of Spill Path (outside berm)

- Roundness/ Deformation Report

- Verticality Report

Using laser scanning for your tank inspection needs, results in a higher degree of accuracy and confidence in a shorter amount of time than experienced prior. Here are some potential scenarios where you might want to consider utilizing laser scanning for tank inspections:

- As-Built Documentation

- Asset Documentation

- Construction / Repair Planning

- Environmental Concerns / High Consequence Areas

- Modeling / CAD

- Pre-planning for Focused Inspections

- Traditional API 653 inspections

- Mandated and or Jurisdictional Requirements

- 100% Photo Documentation

- Virtual Walk-throughs and Walk-arounds to be Shared Internally with Stake Holders.

The best part about this service is the cost savings you can realize over traditional methods. The field scanning is very efficient, and the software automation allows for deliverables to be turned over in a short amount of time.