Finite Element Modeling Capabilities

Many engineering structures and components involve complex geometry, material behavior and loading. Finding the stress, deformation, temperature, and pressure or assessing mechanical behaviour of such structures is not typically possible through analytical methods, so we turn to numerical ones. In the numerical approach, the mathematical equations that describe the physics of the problem are approximated based on different types of discretization over space and time.

Finite element analysis (FEA) is one of the popular numerical methods due to its versatility and the fact that it is very well developed.

At Applus+, we utilise FEA as one of the main steps in most of the engineering studies we provide for clients. Here are some examples of the types of the FEA our teams have produced:

- Modelling of new and mature oil and gas assets covering stress, pressure, thermal and seismic analyses, as well as vortex-induced vibration analyses

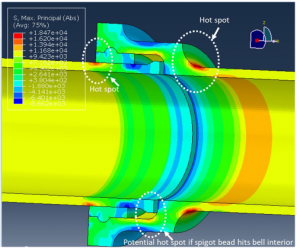

Figure 1 Bell and spigot joints

Figure 2 FEA of bell and spigot joint

- Analysis of pipelines subjected to blast vibrations from nearby mining, quarrying and construction activities

- Simulation for failure and collapse under severe loading on various types of structures such as pipelines, offshore structures, buildings, bridges, welding, pressure vessels and pipe connections

- Simulation of different stages in the life of an asset, from construction and commencement through to installation and operation under assumed or measured damage and flaws

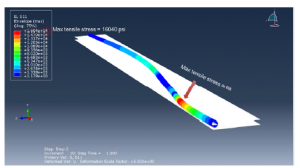

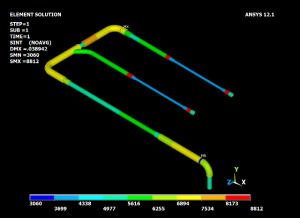

Figure 3 Pipeline installation

Figure 4 FEA of pipeline installation process

- Identification of allowable stress limits under geological loadings, such as subsidence, frost heave, landslide, and fault crossing using a pipe-soil interaction simulation.

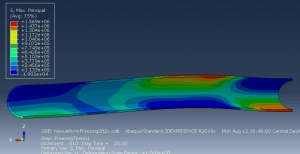

Figure 5 FEA of non-uniform freezing of a pipeline

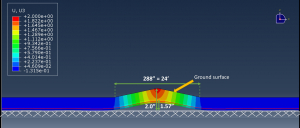

Figure 6 FEA of pipeline under frost heave loading from the top

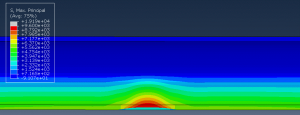

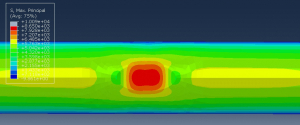

Figures 7 FEA of a local corrosion patch – front view of the pipe

Figure 8: FEA of a local corrosion patch – bottom view of the pipe

Collapse simulation of a high-rise building due to excessive external loads:

In addition to the typical FEA, At Applus+, we have knowledgeable and experienced engineers to offer:

A) An automatic or semi-automatic FEA simulation platform for assets and facilities where clients can upload the 3D scans and receive a digital twin model, as well as the FEA model of the investigation required

Figure 9: 3D scan model of a facility

Figure 10: FEA model of the facility

B) Multiphysics simulations such as pipe-soil interactions and thermo-hydro-mechanics coupling, as well as fracture modelling, damage modelling and fatigue analysis

C) Parametric and sensitivity analysis using FEA modelling, which greatly assists clients to evaluate product or assets more concisely, and allows for multiple “what-if” scenarios to be tested quickly and effectively

D) Statistical analysis to predict unknown features from the results of the multi-thousands FEA simulations

E) Fitness for Service (FFS) assessment, under API 579 and BS 7910, which requires a FEA method in some cases to compute longitudinal and hoop stresses

At Applus+, we can address an array of situations when assets experience crack-like flaws, stress-corrosion cracking, dents, gauges, laminations and blisters, as well as performing remaining-life analysis under cyclic fatigue loading

Contact us for more information about our capabilities for finite element analysis (FEA) and finite element method (FEM)