Evolution of IWEX technology

In the context of advanced non-destructive testing (NDT) methodologies, Applus+ has operated in the arena of introducing to market some cutting edge, and industrial leading technologies. Synergising the Applus+ Technology Centre with in-field application by our service departments is where we believe we can separate ourselves from the competition in the NDT field. At Applus+ UK we have extremely knowledgeable and experienced NDT technologists who are bust trialling our portable IWEX system for in-service Phased Array Ultrasonic NDT operations.

Leveraging from the international success of the 4th generation (4G) new build girth weld inspection system, the intention is to introduce the 6G portable IWEX inspection system with the release of the international codes, both:

- ASME V article 4 mandatory appendix XI – Full Matrix Capture

- ISO 23864 – Non-Destructive testing of welds, Ultrasonic Testing, use of semi-automated full matrix capture/total focusing technique.

Currently in operation, in the marketplace, is the 4G IWEX system which now has full approval for inspection on new girth weld construction. The birth of the technology in and around 2003 has evolved into becoming a superior product in its application in 2018 and beyond. Speaking to Niels Portzen, who invented the technology, his take on the trajectory of the IWEX system is that “development of the IWEX technology would separate us from our competition” he went on to say “with our ultrasonic imaging technology we have the edge to sensitise the results output that we deliver as a service-based company. We can tailor make a solution (regarding sensitivity and resolution of results) to our client’s deliverable requirements and their needs.”

So, what exactly is IWEX, you ask?

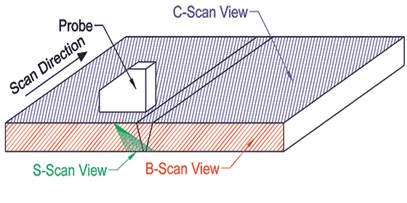

Basically, Inverse Wavefield Extrapolation (IWEX) uses the same principles of ultrasound employed on weld inspections currently, except for a few differences. It uses multiple sound transmitters to generate and create an ultrasonic image. This is the same principle of Phased Array Ultrasonic inspection.

Phased Array Ultrasonic Inspection creates a better, and more permanent, image of weld indications from multiple angles whereas conventional UT only uses one fixed angle of inspection per scan. In addition to what phased array does, IWEX uses multiple transmitters and multiple receivers to gather gigabytes of data to allow difficult to reach areas to be “seen” ultrasonically. This is the same as Full Matrix Capture (FMC) and Total Focusing Method (TFM). So how is IWEX different then?

What sets IWEX apart is a reconstruction, in the software, of all possible transmit and receive signal combinations, fired from the probe at a given inspection time. Using information about inspection material properties (acoustic velocity) and geometry, a model of the test item can be created in an image space containing pixels. All the collected data (A-Scans) are time-shifted to a zero point so that their exact location on the pixel map can be plotted and hence, the display or presented images can be shown. The location in the space of the pixel is known in the software, so reflected UT signals are placed in their “calibrated” locations. Then, an image is produced that is understandable to anyone looking at it.

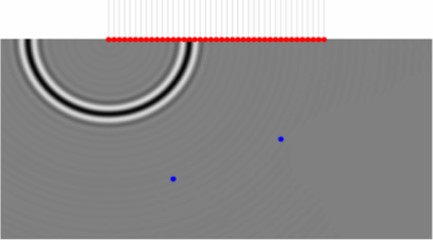

Below is an example of each of the elements firing and each of the elements receiving the reflected signals to create a data set and an image.

|

|

|

| From sound exiting from transmitting elements (One firing element is shown for visualisation purposes) |

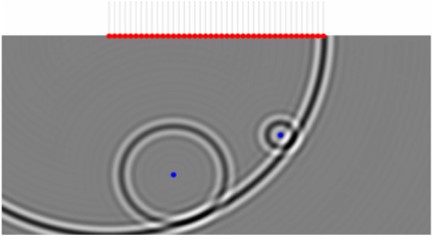

From sound reflecting from reflectors. |

From sound received by the receiving elements to be processed into readable data. |

So, the development of the technology to apply it to in-service inspections as an off-the-shelf inspection tool is in its final stages of trial and rollout. We can create that niche for our clients where they are applying existing technology (full matrix capture and total focusing method) and improve on that with our services. We are moving forward with the 6G platform to provide that superior result presentation to our customers.

As a service-based company, with back shop support and development in the research department and Technology Centre, currently, Applus+ UK is striving forward to bring this technology to our clients to deliver useable engineering results from advanced NDT inspections.

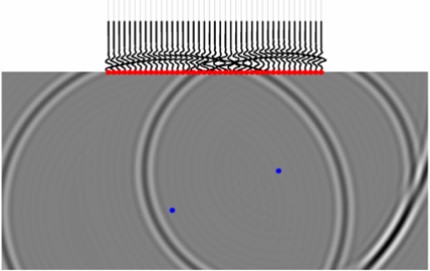

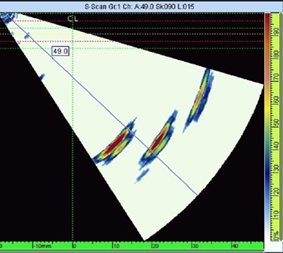

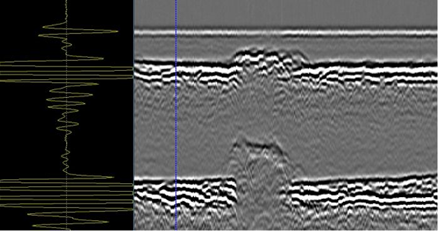

The portable IWEX will set itself apart in the in-service inspection market by taking ultrasonic results which can often be subjective, as seen below, and creating value-added displays based on the data processing by wave extrapolation.

|

|

.2022-10-20-10-42-36.png) |

| Conventional UT A Scan | Phased Array Sector Scan | TODF Scan |

|

||

| View of an ultrasonic Weld scan | ||

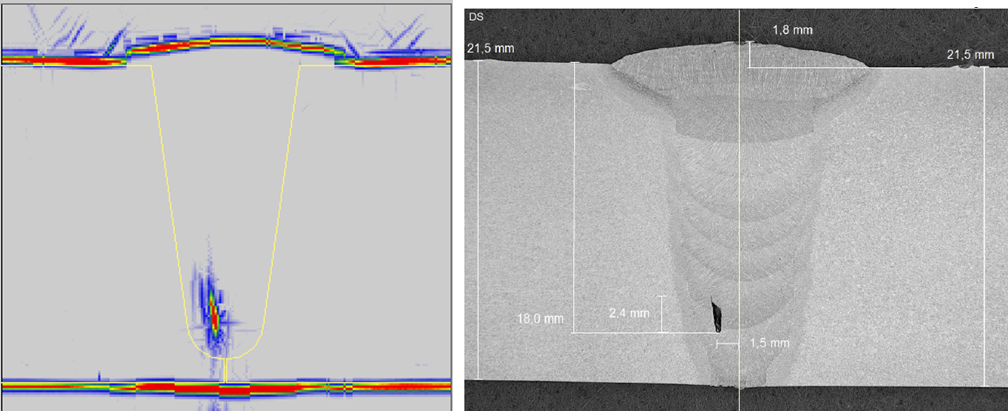

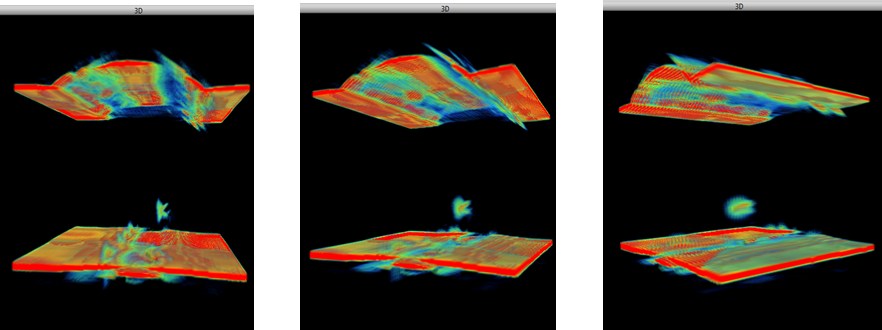

The displayed data seen below shows: data before image processing, and then 2D, as well as close to interactive 3D imaging.

|

|

| Side view of welded sample cut through to display defects. | Unprocessed IWEX (FMC) data from weld defect. |

|

|

IWEX Display in interactive 3D presentation |

We are actively performing trials in the UK as well as all Applus+ regions to develop this technology. This will ensure we can create tailor-made solutions for our clients. The existing technology stands on a superior ultrasonic platform, outperforming many competitive products in the market currently and it will not be long before the 6G portable system will be in the market.

Publication by: Grant Meredith - Multi-certified NDT level 3 Technical Manager, Applus+ UK