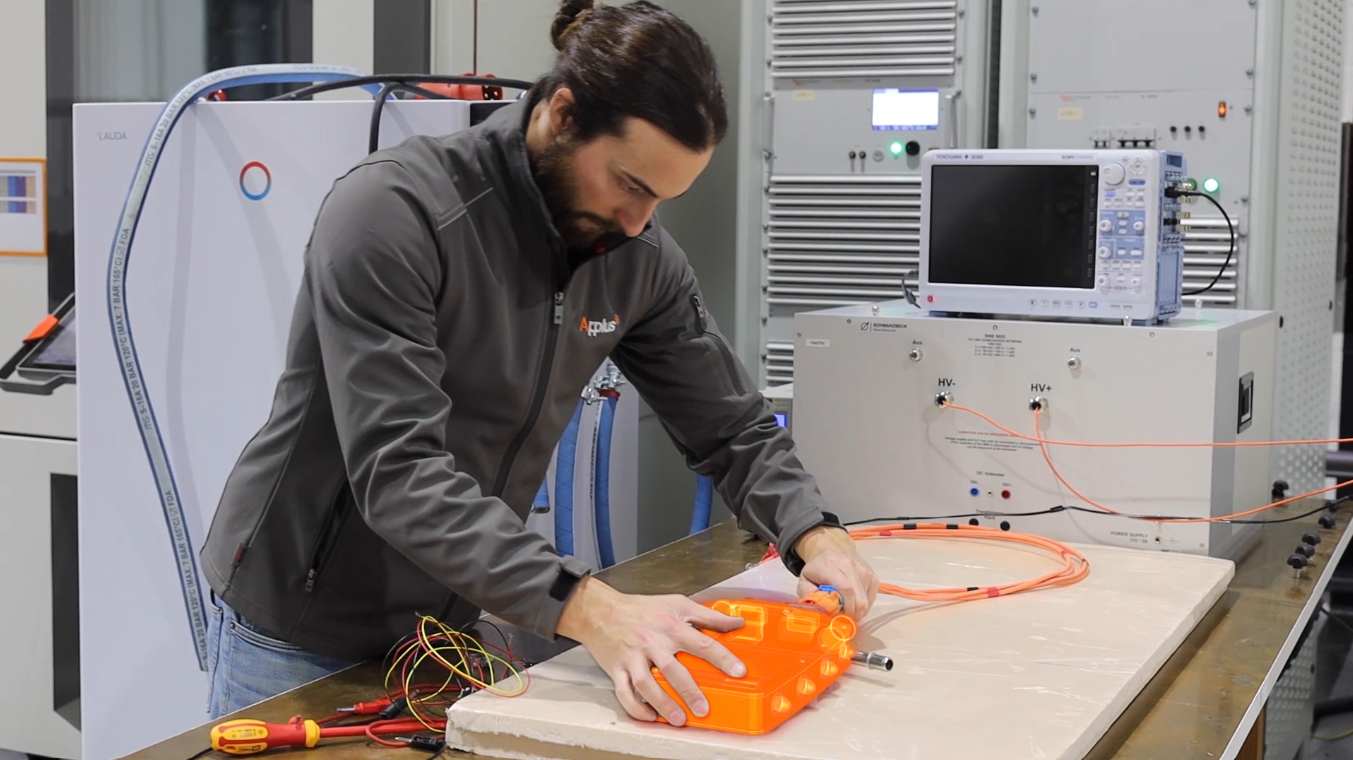

Our state-of-the-art laboratories and technical expertise support manufacturers and OEMs in the development of next-generation electric-powered vehicles through controlled testing environments that validate HV systems across all critical parameters.

We have a network of fully equipped testing laboratories for test HV components in the USA, Europe and China, with specialized tests benches, an all the auxiliary equipment required to test power electronics (Power Supply Units, filters, LISNs, Coolant Systems, etc.)

HV Components & Systems Tested

- Power Electronics Components

- HV Power Distribution units

- DC/DC Converter

- Inverter Systems

- On-board chargers

- HVAC Compressor

- Electrical Heater

- HV Cooling Pumps

- Charging Socket & On-Board Charger

- BMS testing

- Fuses & Contactors

EMC Testing Capabilities

- Emissions testing: DC to 40 GHz

- Immunity testing: DC to 40 GHz

- Electric & Magnetic low frequency field testing

- EMF measurements

- ESD testing

- Power electronics characterization

Environmental Testing

- High Thermal gradient chambers

- Dedicated high heat compensation chambers for thermal applications

- Large climatic chambers (> 10 m3)

- Water protection & corrosion testing

- Salt spray & thermal shock testing

- Damp heat & thermal durability

- IP protection validation

Electrical Testing

- Testing up to 1500 V and 2000 A

- Voltage ripples

- HV load dump

- Short circuit tests up to 30 kA

- Insulation resistance & dielectric strength

- Efficiency & service life testing

- Over-temperature protection testing

- On/Off durability validation

Abuse & Mechanical Testing

- Impact testing up to 35 km/h velocity

- Maximum test mass: 1500 kg

- Drop & free fall testing

- Stone impact & dust testing

- Vibration testing

- Hosedown testing

- High-frequency optical tracking

- High-speed camera analysis

Virtual Development

- Hi-fidelity simulation of power electronics

- Inverter calibration benchmarking

- Model-in-Loop to Power-Hardware-in-Loop

- Electromagnetic modeling & validation

- Material characterization & CAD modeling

- Switching ringing effects analysis

- Technology trend surveillance

- Performance optimization studies

Standards & Compliance

Our testing services comply with comprehensive international and manufacturer-specific standards:

International Standards

- DIN EN 60068, ISO 16750

- ISO 7637-4, CISPR 25, ISO 11452-X

- ISO 21498-2

- UNECE Regulation100, G.T.R. No. 20

- UNE-EN 60529, FMVSS 305

- ISO 6469-3, ISO 13063

- UNECE Regulation 10

Manufacturer Requirements

- LV 123 & LV 124

- BMW GS95002-3, GS95023, GS93025

- Ford FMC1280

- Mercedes-Benz MBN10284-3, MBN LV 123

- Nissan 28401NDS02

- PSA B21 7112, B7112

- Renault 36-00-811

- Volvo 31857169

- VW 80300

Regional Standards

- GB/T 18384 (China)

- EN17128 (PLEV)

- EN15194 (EPAC)

- Various national regulations

State-of-the-Art Equipment

HV Power Systems: HV Power Supply up to 1500 V, HV current Supply up to 2000 A, HV/LV Electronic Load, grid emulators, battery simulators up to 500 kW

Super Capacitor Bank: 18.57 Farads capacity, 46.9 mOhm internal resistance, 430 V-8 kA discharge, 1.7 MJoule energy

Specialized Equipment: HV Input Filters, HV Shielded LISN, Power amplifier & HF transformer solutions, HV 4 Quadrant Amplifier System

Cooling Systems: Chiller systems (water/oil cooling), cold water circuit for customer chillers

Analysis Systems: High precision sensors up to 2000 A, high-speed cameras, remote monitoring systems

Complete Service Portfolio

Design Validation Plans (DVP)

- Comprehensive verification plan development

- Test list design and optimization

- Sample quantity optimization

- Efficient test execution planning

- Multi-domain testing coordination

Consultancy Services

- Electrical high voltage safety

- Insulation coordination

- Regulatory compliance guidance

- Technology trend surveillance

Remote Services

- Remote monitoring and assistance

- Customer participation in setup

- Office-based test monitoring

- Reduced transportation costs

- Real-time collaboration

Development Support

- Prototype to serial production (SOP) validation support

- Complex setup design

- Custom testing solutions

- End-to-end lifecycle support

- Eco-innovation initiatives