Engineering Services

Applus+ provides advanced engineering solutions for the development of electric motors and electric drive units, supporting clients from concept to full vehicle validation. Our multidisciplinary teams combine expertise in electronics, electrical, mechanical, and NVH engineering to optimize performance, reliability, and compliance.

- Virtual development and simulation: 1D/3D modelling for current patterns, heat distribution, electromagnetic flux, torque response, and acoustics.

- NVH analysis: Acoustic optimization and troubleshooting.

- Electromagnetic modelling: Design optimization and early identification of flaws such as hot spots or flux leakages.

- Simulation, test, and homologation planning: Generation of validation plans and prototype lists aligned to customer and regulatory requirements.

- Multidisciplinary teams: Holistic development with expertise in electronics, mechanical, and NVH.

Testing and Validation Services

Our testing services provide comprehensive validation of electric motors and electric drive units, ensuring readiness for market introduction and compliance with international standards.

The test to evaluate the e-motor:

- Performance & Characterization:

We conduct nominal and peak torque/power measurements (including R85 certification), efficiency mapping, and trend analysis during ageing. Additional tests include thermal characterization, derating evaluation, back electromagnetic force, locked rotor, and park lock actuation.

- Endurance & Durability:

We perform long-term durability cycles with a wide range of temperatures, with independent control for ambient and for coolant, powerful battery simulators, and humidity control. We can test following customer-customized profiles and 24/7 automated operation. Our process includes rapid failure reporting and damage pre-detection systems based on vibration analysis.

More Testing Capabilities

- NVH Testing: Mechanical, vibration and noise tests are performed under various climatic conditions to ensure the robustness of the motor and drive unit.

- EMC Testing: We carry out advanced electromagnetic compatibility tests in both static and dynamic conditions, using bi-directional dynamometers to simulate real driving and regenerative braking scenarios. These tests validate the integration of the e-motor within the vehicle’s electronic architecture and ensure compliance with OEM and regulatory standards.

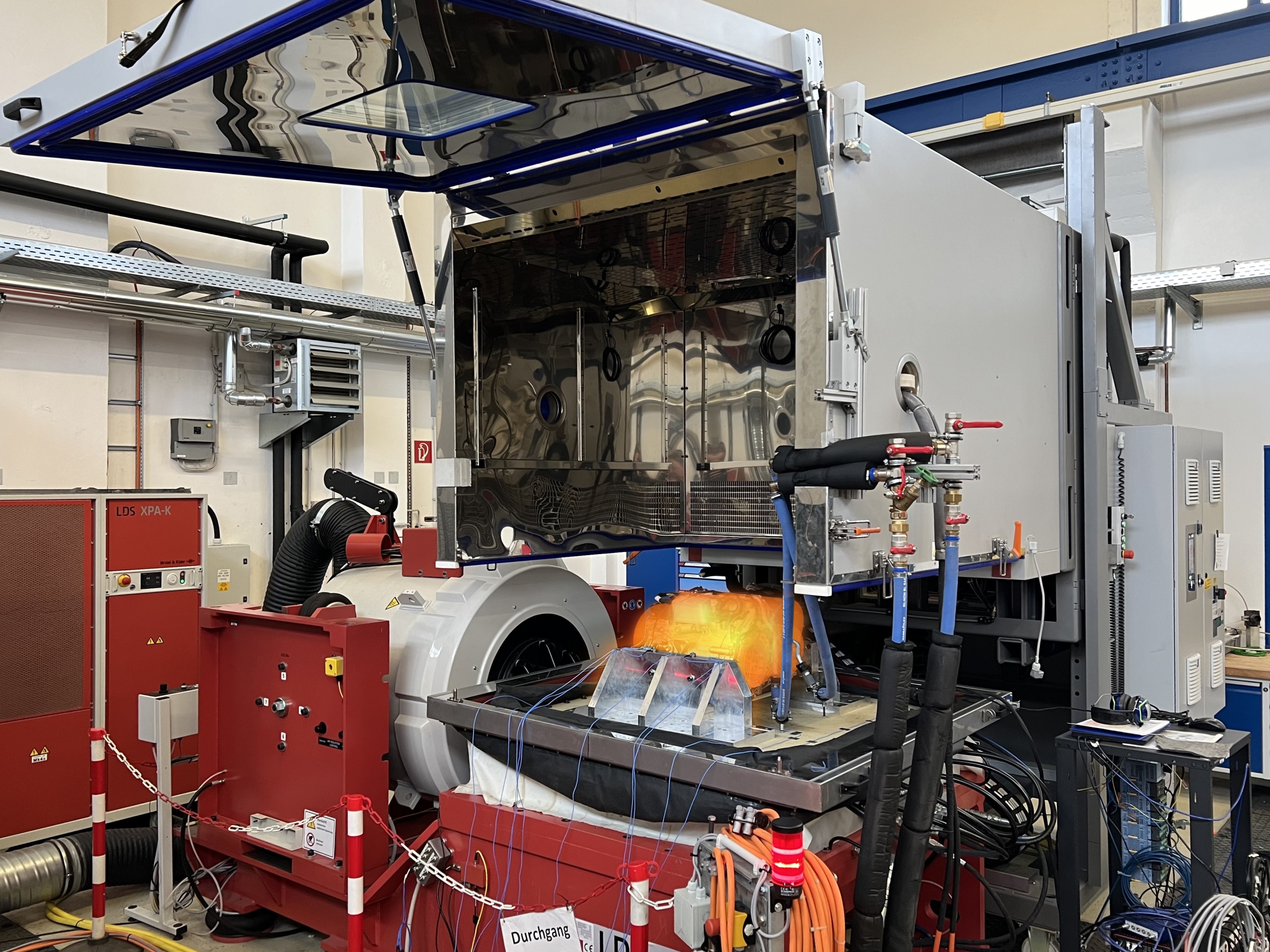

- Environmental & Climatic Testing: Our facilities allow for testing in climatic chambers from -40 ºC to 120 ºC, with independent control of ambient and coolant temperatures, humidity control, and exposure to water, dust, damp heat, mechanical and thermal shocks.

- Component testing: We test e-motor rotors and stators, power electronics including DC/DC converters and onboard chargers, plus HV ancillaries such as PTC heaters and heat pumps, ensuring all components meet stringent performance standards for electric vehicle applications. Discover our capabilities for HV component testing.

Facilities, Capabilities & Equipment

- High-precision data acquisition: Advanced sensors and CAN-based control equipment for detailed measurement of mechanical, electrical, and thermal parameters.

- Battery simulation: Battery simulators up to 400 kW / 1000 V / 1400 A for realistic power supply during testing.

- Climatic chambers: Large chambers with independent control of ambient and coolant temperatures, plus humidity control.

- Electrodynamic Shakers: Advanced test facilities that combine vibrations and shock capabilities (up to 200 kN) combined with environmental and electrical test equipment.

- Bi-directional dynamometers: For Functional/Performance and EMC testing with the motor in motion, supporting both static and dynamic test configurations.

- Custom test fixtures: Designed and manufactured in-house for each project’s specific needs.

Validation Plan (DVP)

Full DVP generation and execution for electric motors and drive units, covering all required test types for worldwide OEM standards.