Wall Thickness Measurements

Manual UT wall thickness measurements is a technique using high-frequency sound energy to conduct examinations and obtain thickness measurements. In an ultrasonic thickness measurements (UTM) inspection, a straight beam is introduced into the test object perpendicular to the surface and round-trip time is measured. Quantifiable information can be gathered for detection of localised or general wall-thickness changes.

Ultrasonic Shear Wave

The ultrasonic shear wave method is a technique which encompasses angle beam ultrasonic testing to identify subsurface anomalies not found directly underneath the transducer itself. Shear wave ultrasonic testing uses ultrasonic energy that is reflected back to the transducer from indications within a material and or weld. This is displayed as an A-scan, from which an operator can review the relevant information to assess the integrity of the component.

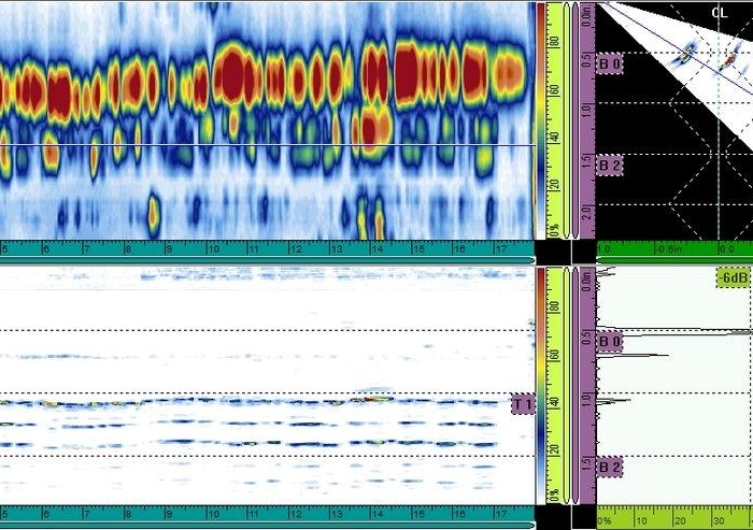

Ultrasonic C-Scan

Automated ultrasonic C-scan is a technique that utilises ultrasound and mechanised scanners to build a comprehensive plan view of the component being inspected. Typical plan-view imaging is displayed in colour-coded maps according to the thicknesses obtained throughout the inspection area. Calibrated dual-axis encoders provide a scale map to measure the lengths and widths of the indications found.

EMAT Inspection

Applus+ has developed proven and tested procedures for EMAT NDT and EMAT ultrasonic testing in accordance with applicable codes. The NDT technicians at Applus+ are rigorously assessed on data acquisition and interpretation for EMAT ultrasonic testing, with both internal and external assessment.

Guided Wave Ultrasonics

Guide Wave Ultrasonic Testing has been identified as an effective pipe-screening technology capable of detecting, locating, and classifying corrosion defects. The technique enables volumetric screening of pipes, which covers 100% of the cross-sectional area of the pipes within the diagnostic length of the test. In most cases, tens of meters can be screened from a single test position, making it a rapid and cost-effective non-destructive testing (NDT) method. Additionally, access to the pipe under test is only required at the test position (remote inspection), which makes Guided Wave screening technology an ideal solution for inspecting pipes that are costly to inspect using other methods, for example, buried sections of road crossings or insulated pipelines.

The Wavemaker Pipe Screening System is a screening method that utilizes ultrasound. A probe ring is placed around the pipe and transmits guided waves through the pipe in either direction of the probe ring. The pulse echo type operation provides information on features and/or different types of defects at their positions and severity. The guided wave testing can be either performed as a single inspection or repeated inspections from the same location, which can be used for monitoring purposes (gPIMS® Monitoring)

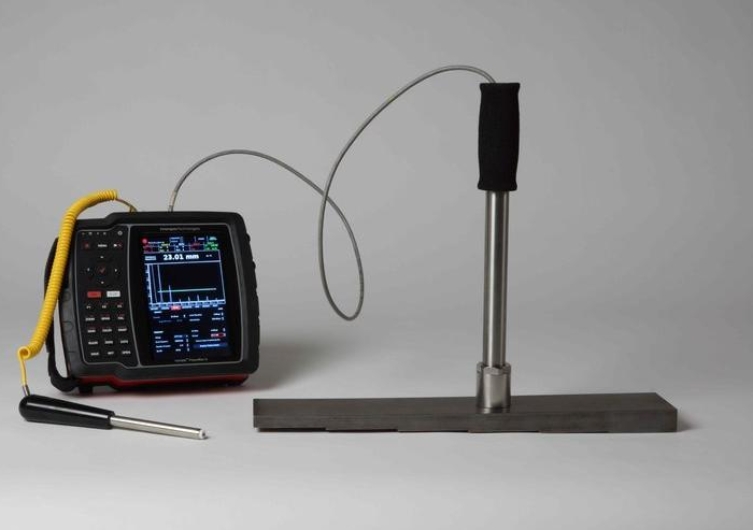

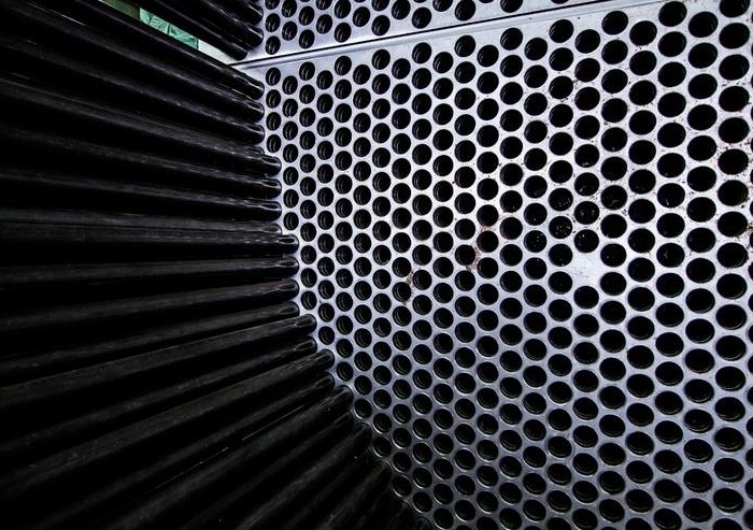

IRIS Inspection - Internal Rotating Inspection System

IRIS (Internal Rotary Inspection System) is an ultrasonic inspection technique developed to measure the wall thickness of tubes from the inside. It can be applied to a wide range of materials like stainless steel, carbon steel, duplex steel, copper alloys, and more. Typical applications include the inspection of heat exchanger tubes, fin-fan tubes, and boiler tubes. It can be used in addition to or instead of one of Applus’ tube inspection techniques: eddy current, RFT, or PSEC.

Phased Array Ultrasonic Testing – PAUT NDT

Phased array ultrasonic testing (PAUT) provides a fast and reliable UT inspection solution for flaw detection and characterisation across multiple presentations simultaneously. Phased array NDT technology uses multiple elements fired in quick succession to produce beams that can be steered, swept and focused electronically. Inspections across multiple angles are performed concurrently, creating significant cost savings and providing recordable results for further analysis and/or future inspections. Phased array ultrasound is capable of performing multiple applications including NDT welding inspection, CUI inspection mapping, and inspections on composites and components of complex geometry. Through use of accurate scan-planning and beam-steering capabilities, phased array ultrasonic testing increases the probability of detection, while inspection times are reduced to a minimum.

DTI Trekscan

DTI Trekscan is the first free-floating pipeline in-line inspection tool designed to traverse back-to-back one-dimensional (1D) bends, with an optimum speed of one-metre-per-second (2.2 mph). It can run in pipelines previously considered to be 'unpiggable'. The bi-directional tool measures the return echoes of a transmitted ultrasound beam. The amount of time it takes to receive an echo provides highly accurate information on the remaining wall and enables the detection, characterisation and sizing of metal-loss anomalies. Using the latest ultrasonic technology and high-density transducer-carrier design, most refined petroleum products, water and crude oils can be used as a medium to run this tool.

IWEX

IWEX (Inverse Wavefield Extrapolation) is a full matrix capture (FMC) technique using ultrasonic (UT) inspection in which individual A-scans are recorded for each and every element of an array transducer, and these A-Scans are processed in a similar way to seismic processing and medical imaging. Advances in computer-processing hardware and software are making these techniques possible in real-time in the field.

Rotoscan: Automated UT Weld Inspection

Rotoscan is an automated ultrasonic inspection system developed in-house by Applus+ RTD to perform NDT welding inspections of girth welds during the construction of long-distance pipelines. Developed for both onshore and offshore NDT pipeline inspection, the Rotoscan UT weld inspection system can detect and measure welding imperfections within the weld and associated heat-affected zone, determining both the circumferential length and the through-thickness dimension. The system combines a low false-call rate (FCR) with flaw-sizing capabilities, a user-friendly color presentation using customized software, and the storage of results.

Short Range LORUS

Various locations within a facility have the potential to see the release of product due to hidden corrosion. These locations are referred to as 'difficult to inspect' and include equipment and piping which is partially buried, soil-to-air interfaces, concrete-to-air interfaces, piping encased in a sleeve or concrete, the support-to-equipment interface known as the 'touch point' and the critical area inside a storage tank. Unless the equipment is lifted, taken out of service or un-earthed, the owner/user is usually unaware that issues exist. LoRUS (Long-Range Ultrasonics) is capable of detecting external or internal corrosion within ferrous or non-ferrous material at a distance of up to 90cm (3 feet) depending on the material and its surface condition, corrosion, coatings and temperature.

Time-of-flight diffraction (ToFD) Ultrasonic Testing

TOFD ultrasonic testing (UT) is typically used in conjunction with a a phased-array application as a rapid screening tool for the detection and sizing of circumferential- and axial-weld imperfections. In ToFD ultrasonic testing, the ToFD NDT setup involves placing two transducers on opposite sides of the area to be inspected. Sound waves are then refracted into the specimen at angles appropriate to component thickness.