Single sided Phased Array: Developments in weld ultrasonic inspection

Applus+ is testing single sided Phased Array, consisting of an ultrasonic method which is used in pulse-echo mode and allows Applus+ to carry out a volumetric welding test from only one side of the weld.

This is an ultrasonic method which allows a volumetric welding test from one side of the weld.

It involves an ultrasonic inspection application on welded joints which only can be approached from one side, such as pipe-fitting, pipe-flange and pipe-valve, by means of Phased Array. In other words, single-sided Phased Array.

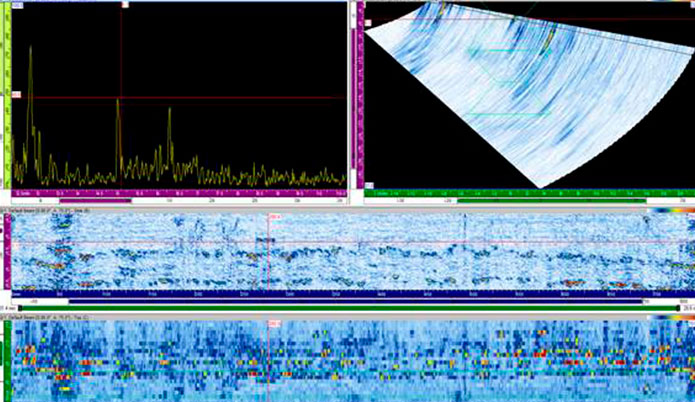

The main advantage of Phased Array regarding conventional ultrasonic examination is the representation. The ultrasonic signals become clearer, which offers an advantage in the analysis in terms of sizing and monitoring, and detection will mainly be based on amplitude response with reference reflector.

The test plan for this method consists of 9 parts, all necessary for the research on the single-sided Phased Array technique. The plan is made to find a good way to examine a weld from one side using Phased Array.

- First the theoretical part: Creating scan plans whereby all parameters, which are necessary for carrying out the examination, are recorded and visualized.

- Then the practical part: Scanning welds with known defects with the theoretically determined parameters. All obtained data is analyzed with the detected indications being measured in length and recorded.

- The comparison: The results are compared with the X-ray results with a very positive result. For the tested welds single sided Phased Array detected more of the known indications than the current technique on that kind of welds viz X-ray.

- The practical feasibility: Soon the next test phase will start with scanning field welds and comparing with the x-ray results of those welds.

To summarize, in the first test phases this technique shows a fast and reliable solution for weld quality on welds which can only be approached from one side, while inspection times are reduced to a minimum. The result of the weld quality can be given in a couple of minutes after scanning. Another big advantage with respect to x-ray is that the environment does not have to be evacuated.