Computed Radiography CR

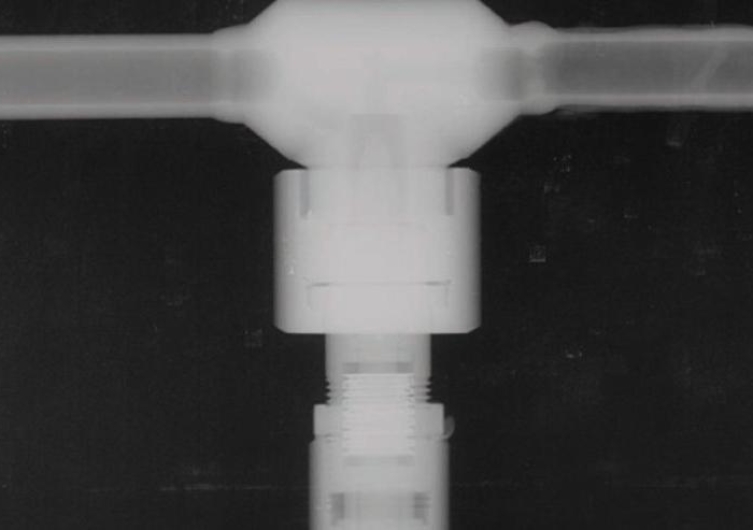

Computed radiography (CR) NDT uses a filmless process to create digital, 2-dimensional radiographs. Digital radiography NDT provides radiographic images from a computer using the same conventional radiography exposure equipment. Computed radiography eliminates the need for chemical processing, uses lower source strength, enables smaller boundaries and yields quicker results. Computed radiography NDT provides images with a higher resolution and definition, providing greater detail for evaluation. Data storage and retrieval could not be simpler and information can be shared via the internet.

Computed Radiography CR

DOWNLOAD PDF VERSIONDigital Radiography / Direct Radiography (DR)

Digital radiography or direct radiography (DR) is the next evolution in inspection of in-service systems with minimal downtime or preparation. DR has the ability to inspect pipelines during operation without having to remove insulation and with no temperature restrictions. This is a filmless radiographic technique that requires no processing, is wireless and yields results instantaneously. Data storage and retrieval could not be simpler and information can be shared via the internet.

Digital Radiography / Direct Radiography (DR)

DOWNLOAD PDF VERSIONRayscan/Tankscan Real Time Digital Radiography

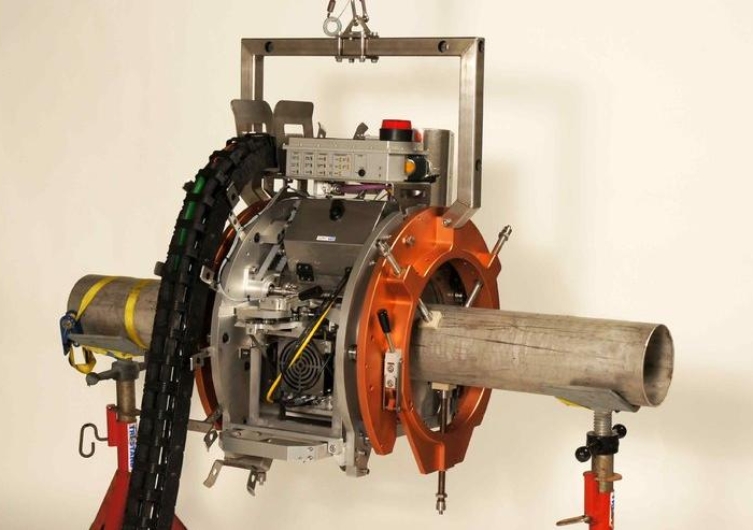

RTD Rayscan and Tankscan are Applus+ solutions for real-time digital radiographic (RTR) inspection used in radiography NDT, which uses advanced technology in direct radiography (DR) techniques. Real time digital radiography involves the filmless conversion of data into a high-resolution digital image of the entire weld and can be performed within a single scan. Rayscan is a RTR inspection that can be used as either double-wall single image (DWSI) or single-wall single image (SWSI) and can inspect pipes with a diameter range from 5cm to 142cm (2" to 56"), as well as horizontal and vertical tank weld seams.

Radiographic Testing RT FILM

Radiographic Testing (RT) is one of the most fundamental volumetric-testing methods performed in industry and radiography NDT. Film radiography, which utilises either X-ray or gamma radiation generated from a tube or from an isotope of Iridium-192, Selenium-75 or Cobalt-60, has been the most widely used application for volumetric inspections. RT NDT has the ability to: penetrate wide ranges of material with varying densities to detect internal defects in weld quality; profile in-service systems to determine if corrosion or erosion is present; evaluate castings for fabrication flaws or foreign objects; and detect damage in composites.